Aluminum in die casting

Complicated geometries for most diverse fields of application can be produced by aluminum die casting. The die cast material is characterized by a high permanent strength and ductility as well as excellent dynamic strength. As a result, stress peaks resulting from sudden strains are automatically absorbed, and even vibration stress combined with tensile load can be easily coped with.

There is no need for costly and complicated assembly, screw-fastening or riveting with intelligent solutions made of die cast aluminum requiring short manufacturing times, and the material is excellently suited to machining. For this reason, aluminum is gaining more and more importance in machinery construction and electrical engineering, where it is used for manufacturing components such as enclosures, running wheels, sections and fittings. In automobile construction, the use of aluminum has become a key factor for success due to its low weight.

Its material properties combined with innovative manufacturing methods are able to satisfy the demands for lower fuel consumption, reduced emissions, high efficiency and corrosion resistance in an ideal manner. For these reasons, the proportionate share of aluminum used in all kinds of vehicles has been growing continuously for many years, and the material will be more and more indispensable in the future.

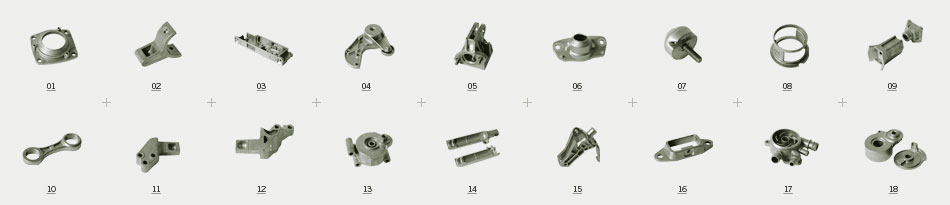

The focus of our production is on die cast aluminum parts for the automobile industry, such as components for traversing gears, engines, gear boxes, hinges and bearings made of rubber-metal compounds, as well as die cast parts for machinery construction or the electrical industry, including fittings, enclosures and mounting plates.