Zinc in die casting

Zinc is a material that can be ideally shaped through die casting. Due to its low melting point and extraordinarily tight solidification intervals, its temperature-induced shrinkage is very low, and in addition, very high injection rates can be achieved combined with excellent reproducibility. Die cast zinc components are characterized by high hardness and strength, as well as precision, evenness, high accuracy and compliance with especially strict dimensional tolerances.

Compared to conventional manufacturing methods, highly complex geometries with clean, smooth surfaces suitable for high-quality finishes as well as sharp, distinct contours can be obtained. Fine reliefs, drilled holes, eyelets, letters and attachment points can be manufactured to size in a single working process, and pins, bolts or other elements made of different materials can be sealed in.

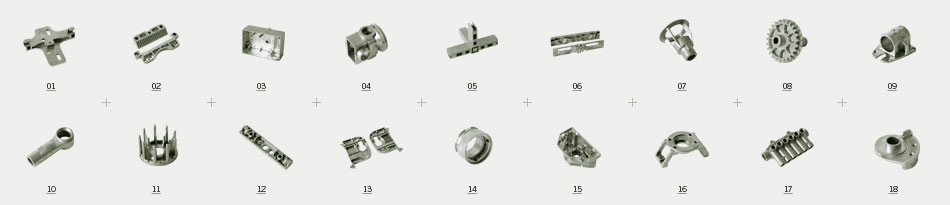

We produce fittings, pump housings, lids, flanges and hubs for the lock and fittings industry and for machinery construction. For the automobile industry, we have developed solutions that have become indispensable Die cast housings, handles, fixing devices, mechanical parts, toothed wheels, covers etc. feature a high dimensional stability and finest details true to shape. With its excellent shielding property, zinc is particularly beneficial for housings or covers for electronic parts.

The surfaces of die cast zinc products are of an excellent quality, not least because of the high-precision die casting molds. If any additional properties are required, we will be pleased to offer surface finishing that suits your needs.